In the world of soundproofing, one of the most mysterious things is an anechoic chamber. For those unfamiliar with this term, it’s a soundproof room that absorbs all sounds, echoes, and reverberation. They are used in audio production and acoustic testing to measure sound levels accurately.

What is an Anechoic Chamber?

It’s a room designed to completely absorb reflections of either sound or electromagnetic waves. They are also sometimes known as reverberation chambers or RF quiet rooms. They are routinely used in acoustics laboratories and by the automotive, aircraft, and electronics industries to conduct experiments and test products for noise and vibration reduction.

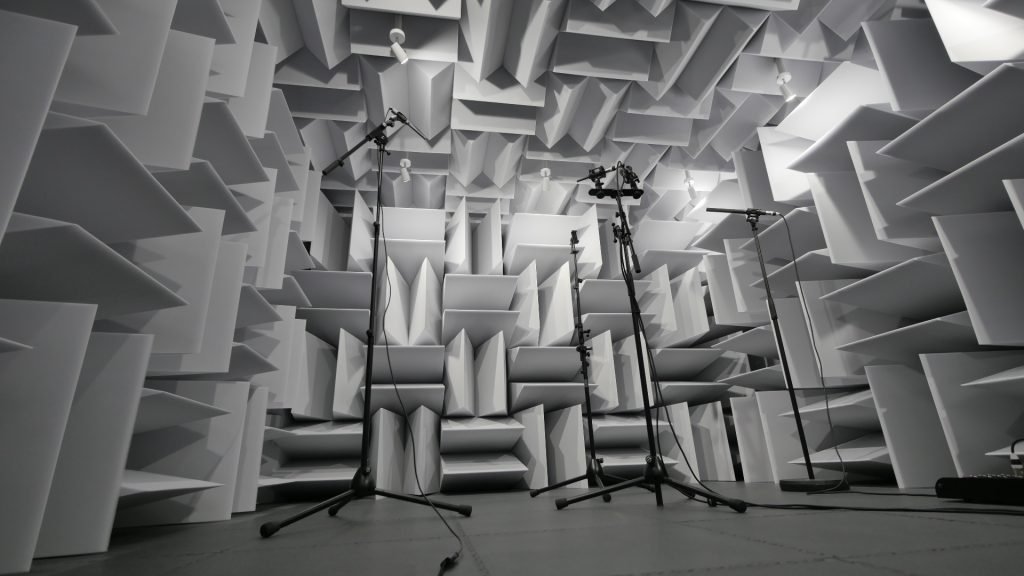

They are usually constructed with materials that absorb sound waves, such as fiberglass wedges or foam pyramids, on all surfaces including the floor, walls, and ceiling. The interior is typically lined with these absorbing materials in a process called sound absorption treatment. This lining absorbs a wide range of frequencies, from very low (bass) frequencies up to very high (treble) frequencies.

Absorption treatments are usually applied to hard surface areas like walls and ceilings to create a more live-sound environment. Soft surfaces like drapes, carpets, and furniture can also be included in an acoustic treatment plan but they do not provide as much absorption as hard surfaces. In general, the more surface area that is treated with absorption materials, the better the acoustics of the room will be.

How do they work?

Anechoic chambers are specially designed rooms that are used for soundproofing and acoustic testing. These rooms are designed to absorb sound waves, rather than reflect them like a traditional room. This allows for more accurate measurements of sound levels and noise pollution.

There are many different types, but they all work by using absorption materials to reduce the amount of sound that is reflected off of surfaces. These materials can be anything from special sound-absorbing foam to fiberglass insulation. The walls, ceiling, and floor are usually covered in these materials to minimize reflections.

Some also have active noise cancellation systems installed. These systems create opposing sound waves that cancel out unwanted noise, providing an even quieter environment for testing.

They are used for a variety of purposes, including acoustic testing of products, measuring noise levels in manufacturing facilities, and conducting research on the effects of noise pollution.

What are the benefits?

It’s a space designed to absorb sound waves so that there is little to no reflection of sound. The word “anechoic” means “without an echo.” This type of chamber is used for acoustic testing and soundproofing.

There are many benefits. One benefit is that it allows for more accurate acoustic testing. When there are no reflections of sound, the measurements taken will be more accurate and reliable. This is important for ensuring that products meet quality standards and perform as they should.

Another benefit is that it can provide a quiet environment for people who need it. For example, people with certain medical conditions or who are sensitive to noise may find relief. This can also be beneficial for employees who work in noisy environments and need a break from the noise during their lunch break or at the end of the day.

Overall, they have many benefits and can be used for a variety of purposes. If you are considering using one, be sure to consult with experts to ensure that it will meet your needs and expectations.

How to build your own

Assuming you have the space, building your anechoic chamber is not as difficult as it may seem. The first step is to construct four walls that are at least eight feet tall and made of a material that will absorb sounds, such as acoustic tiles or panels. The next step is to build a ceiling that is also made of sound-absorbing material. Once the walls and ceiling are in place, you will need to line the floor with a thick layer of foam or another padding to further reduce noise. Finally, you will need to install some fans to circulate air within the chamber.

Once you have all of the materials assembled, the next step is to create an opening in one of the walls large enough to allow you to enter and exit the chamber. Once the opening is created, you can then begin working on sealing up any gaps or cracks around the edges of the wall to prevent sound from escaping. Once everything is sealed up tight, you should then test out by playing some music or other noise inside and making sure that it cannot be heard from outside.